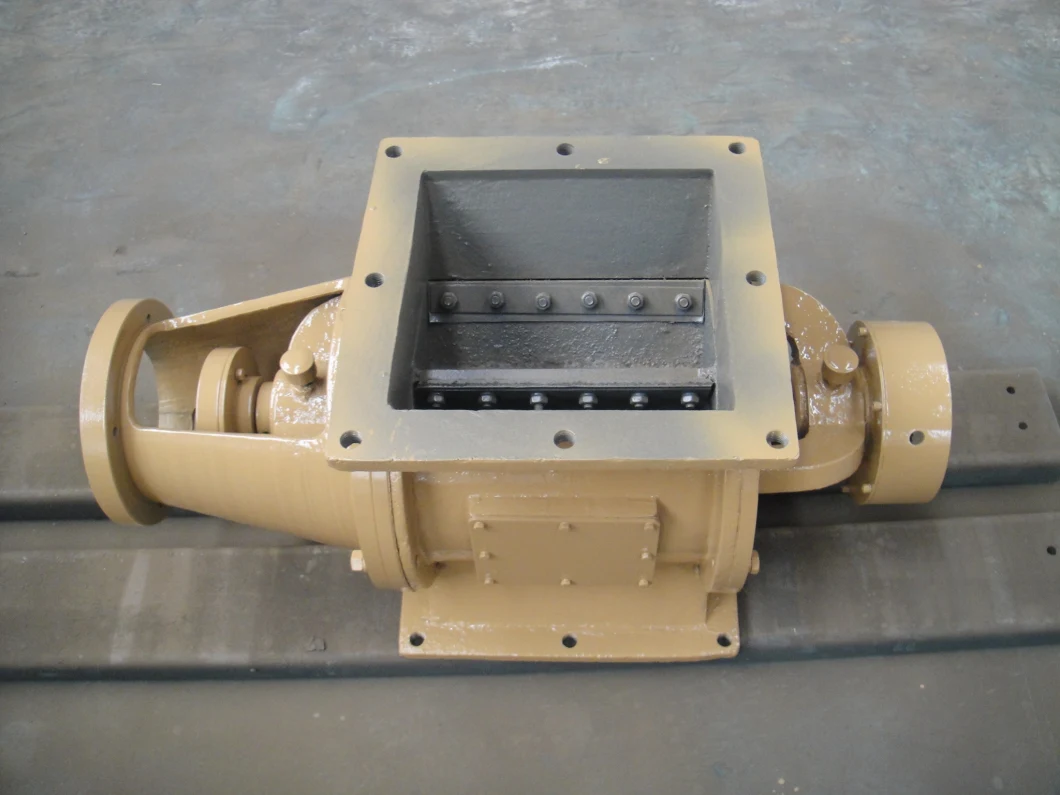

Square Flange Uniform Feeding Impeller Feeder

Introduction The rotary valve is used for continuous and even feeding of dry materials in the form of powder or small pa

Description

Basic Info

| Model NO. | 400*400mm |

| Motor Power(kw) | 20~25 |

| Installation Slope | 10 |

| Chute size(mm) | 6000×1300 |

| Overall Dimension | 6082×2580×2083 |

| Name | Dust-Proof Evenly Feeding Rotary Valve |

| Model | Hgy-500*500 |

| Capacity | 7~106 M3/H |

| Vane Rotating Speed | 34rpm |

| Feeding Size | 200~500mm |

| Motor Power | 1.1~4kw |

| Lubrication | Lubricating Grease |

| Applied Material | Mining, Quarry, Agriculture, Chemical, Bulk Materi |

| Material | Wear-Resistant, Casting Material |

| Inlet and Outlet | Square Flange or Round Flange |

| Driving Mode | Electrical |

| Connection Form | Flange |

| Structure | Single-Eccentric Sealing |

| Seal Form | Auto Sealed |

| Valve Stem | Normal |

| Transport Package | Seaworthy, Wooden Package, Wooden Box |

| Specification | CE |

| Trademark | PK |

| Origin | Xinxiang City, China |

| HS Code | 84283990 |

| Production Capacity | 10 Sets Per Week |

Product Description

Introduction

The rotary valve is used for continuous and even feeding of dry materials in the form of powder or small particles from the upper bin into the next piece of equipment. It is an auxiliary conveyor device. It is widely used as feeding equipment for a materials system in cement, building materials, chemicals, metallurgy and light industries.

Principle

The rotary valve is a constant feeder. This machine is equipped with a BLY series cycloidal-pin gear speed reducer, and it connects rigidly with the main shaft through the output shaft, driving the main shaft and impeller to rotate. The main shaft and impeller rotate simultaneously when the motor is rotating on the impeller. Materials in the upper bin enter into the trough of the impeller through the feed inlet and are conveyed to the outlet by the rotating impeller.

Structure

Firmly structured and exquisitely designed, this machine is assembled with a shell, impeller, end cover of the main shaft and other components, and is equipped with a BLY series cycloidal-pin gear speed reducer.

Technical data

| Model | Capacity m³/h | Vane rotating Speed (r/min) | Feeding Size(mm) | Motor model | Motor Power(kw) | Motor rotating speed (r/min) |

| HGY-200*200 | 7 | 34 | 200*200 | BLY18-43 | 1.1 | 34 |

| HGY-200*300 | 10 | 34 | 200*300 | BLY18-43 | 1.1 | 34 |

| HGY-300*300 | 23 | 34 | 300*300 | BLY18-43 | 1.1 | 34 |

| HGY-300*400 | 31 | 34 | 300*400 | BLY18-43 | 1.5 | 34 |

| HGY-400*400 | 53 | 34 | 400*400 | BLY22-43 | 3 | 34 |

| HGY-400*500 | 67 | 34 | 400*500 | BLY22-43 | 3 | 34 |

| HGY-500*500 | 106 | 34 | 500*500 | BLY22-43 | 4 | 34 |

Installation Notes

1, the rotary valve must be kept clean, especially the inner body of main case.

2, check all fasteners to ensure that the connection is reliable, the machine is (including motor) with good grounding.

3, the flange under and upper the vane feeder must be fixed firmly, make the whole machine is in a state level at the same time

4, check the wiring of motor, make it has start conditions.

Operation notes

1.Pay attention that when start the power supply if motor high heats, you have to stop and inspect, so as not to affect normal operation of the speed reducer.

2.If powder leakage phenomenon is found on the shaft, you should tighten the packing gland bolts on both ends.

3.During operation , check the heat of bearing place, general bearing temperature rise shall not be more than 60 ºC.

4.During operation, if you find abnormal vibration, please stop and exclude it.

5.If found that bolt looseness in the process of operation, it should be tighten.

Lubrication of Rotary valve

Oil in sufficient 00# lithium lubricating grease, within 6-10 months of being put into use, the transmission and bearing parts of rotary valve should be replaced and the grease also need be changed. If rotary valve works in a high ambient temperature, humid or too much air return, please shorten the time of changing the new grease.

During operation, please check the lubrication parts every month.

Above mentioned lubrication time is just the minimum requirements, detailed time should be flexible and depends on the operation condition.

List of Lubrication parts

| No. | Name of Lubrication part | Lubrication material | Lubrication part cycle | Lubrication method |

| 1 | Coupling | 2# lubricating grease | 1000 hours | Lubricator |

| 2 | Bearing seat | 3# calcium base grease | 1 month | Lubricator |

| 3 | Gearmotor | 00# lithium lubricating grease | 6 months | Lubricator |

Our Contact

Send now