Full Automatic Paper Feeding 3 Colors Printing Slotting Die Cutting Machine

Description

Basic Info

| Model NO. | KDYFQ-AZD |

| Driven Type | Electric |

| After-Sales Service Provided | Engineers Available to Service Machinery Overseas |

| Type | Carton Printing Machine |

| Automatic Grade | Automatic |

| Product Name | Carton Printer |

| Voltage | 380V/440V/as Requested |

| Color | 1-5color/Optional |

| Electric Parts | Well-Known Brand |

| Wall Thickness | 50mm |

| Speed | 120-200PCS/Min |

| Frequency | 50Hz/60Hz |

| Capacity | 10sets/Month |

| Transport Package | Wrapped in PE Plastic or Cotton Cloth, Then Packed |

| Specification | Depends on paper size |

| Trademark | KADING |

| Origin | Dongguang, Cangzhou, Hebei |

| HS Code | 84393000 |

| Production Capacity | 100sets/Year |

Packaging & Delivery

Package size per unit product 500.00cm * 200.00cm * 200.00cm Gross weight per unit product 6000.000kgProduct Description

Product Description

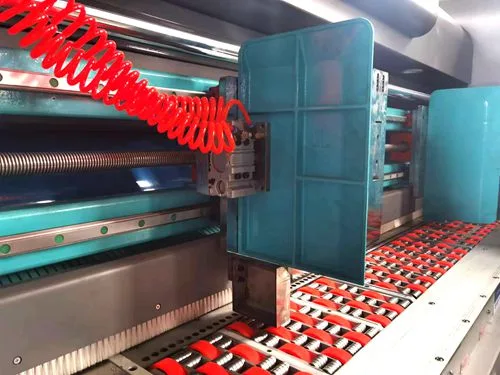

Description:Full automatic paper feeding 3 colors printing slotting die cutting machine1. The whole machine is designed and manufactured according to high requirements and reliable functions, and the operation of the whole machine is designed with humanization, which can perform setting, correction, execution, replacement and memory functions in a short time, and display with accurate data.2. All driving rollers are made of high-quality steel, plated with hard chrome, and the surface is ground.3. The transmission gear is made of high-quality alloy steel, which is heat-treated and ground.4. The main transmission shaft adopts key-free connection to reduce the connection gap and ensure the printing overprint accuracy.5. The automatic oil balance device keeps the oil level of each unit balanced.6. The whole machine is controlled by PLC, with functions of zero reset and memory. (PLC combined with touch screen control can be selected)7. Leading edge feeding method.8. Anilox roller: metal anilox roller or ceramic anilox roller can be selected, and the number of anilox rollers can be selected according to user requirements.

Product Parameters

| Model | Roller Diameter (mm) | Passable Paper Width(mm) | Valid Printing Area(mm²) | Motor Power (kw) |

| YFQ-2000 | φ400 | 1900 | 1700x1200 | 3.0 |

| YFQ-2200 | φ400 | 2100 | 1900x1200 | 3.0 |

| YFQ-2500 | φ400 | 2400 | 2200x1200 | 4.0 |

| YFQ-2000 | φ480 | 1900 | 1700x1450 | 4.0 |

| YFQ-2200 | φ480 | 2100 | 1900x1450 | 4.0 |

| YFQ-2500 | φ480 | 2400 | 2200x1450 | 4.0 |

| YFQ-2800 | φ480 | 2700 | 2500x1450 | 4.0 |

| YFQ-3000 | φ480 | 2900 | 2700x1450 | 4.0 |

| YFQ-2500 | φ530 | 2400 | 2200x1600 | 5.5 |

| YFQ-2800 | φ530 | 2700 | 2500x1600 | 5.5 |

| YFQ-3000 | φ530 | 2900 | 2700x1600 | 5.5 |

Feeding Unit

LEAD EDGE PAPER FEEDER1.Lead edge feeder with vacuum transfer;2.The sliding seat on the feeding table is made of aluminum; alloy, which keep the machine work more smoothly and vibrate less;3.The paper feeding table is steel material. The wall is strong and durable;4.Automatically count the production quantities. touch screen display;5.Equipped with electronic, pneumatic control of skip paper feeding, in order to cope with the larger size cardboard; transport, customers can choose to continue or skip delivery6.The paper carrying is controlled by the cylinder, in the slotting part and stacker are provided with interlocking control switch, as to realize the emergency stop, stop or restore the paper feeding.

REAR/LEFT/RIGHT BAFFLE

1.The pneumatic side flap device (operating side) allows flap frequency to be set on the screen.2.The rear paper -holding frame and the front/left/right side baffles are adopted with electrical adjustment.SEPARATION AND CLOSING1.The machine is separation and combined with electric control device and automatic alarm bell.2.The whole machine is fixed on the track by the main lock cylinder of the feeding part.FEEDING ROLLER1.The cardboard feeding rubber rolls are made of solid steel covered by wear-resistant rubber.2.The paper feed roller adopts embossing roller, and the surface is plated with hard chromium, so that it is wear-resistant and smooth.ZEROING DEVICEWith zeroing and phase memory function, to ensure correct position, reduce cardboard waste.DUST REMOVAL DEVICEThe feeding unit have a dust brush and suction. It can remove the dust on the surface effectively to ensure the clarity of the printing, and reduce paper waste.

Printing Unit

PRINTING ROLLER1.The phase adjustment of the printing roller adopts the planetary gear structure, PC control, digital display, and the printing cylinder can be adjusted 360 degrees. Equipped with positive and negative accuracy adjustment, the machine running and stopping is very stably. And it's easy to change the printing plate;2.The printing roller is grinding and chrome hardening with the latitude and longitude lines center line, easy to hang printing plate;3.Balance correction makes it more stably, and has no effect in high-speed running;4.Hanging printing plate system makes it easy to change;5.Zero function makes the order easy to change. Available foot pedal to changing the printing plate, and equipped with accuracy adjustment function;6.Printing roller left and right electric adjustment range: ±15mm.

Description:Full Auto Vacuum Adsorption Leading Edge Flexo Printer Corrugated Cardboard Cardboard Carton Paper Feeding Printer

VACUUM SUCTION BLOWER

1.With skip feeding function attached to vacuum suction box. All suction wheels are made of ceramic material.2.The vacuum suction box uses light pressure setting to improve printing quality.3.The printing pressure adopt European special high inking technology of piston type regulating 0.015 to ensure accurate to avoid the paste version problems.INK SUPPLY SYSTEM1.The use of one-way pneumatic diaphragm pump automatic circulation of ink, and the anilox roller and printing plate inking system is electric adjustment.2.Using filter to get rid of the impurity and protect the printing quality.3.The inking bucket is made of stainless steel.4.The ink bucket adopts special nanotechnology, non-stick ink, easy to clean.

PHASE ADJUSTMENT STRUCTURE

1.Adopts high precision planetary gear mechanism.2.Printing phase is adjusted by PLC, touch screen and electric control 360 degrees adjustment3.The brake motor has phase adjustment, and phase adjustment wheel can make accurate positioning.

PHASE FIXING SYSTEM

Use clutch or phase adjustment, keeping the original gear meshing point unchanged.

Slotting Unit

CUTTING HOLDER

1.The thickness of slotting knife is 7mm. Imported high quality alloy steel heat treated crescentate blade, which has the advantages of high hardness, good toughness, strong wear resistance and so on.2.The slotting shaft is hard chromium plating on the surface.3.The cutting holder, creasing wheel, position axis can be adjusted automatically.4.Equipped with slotting phase detection device, can record the position of the slotted shaft at any time. Theoretically ensure to return back the right position according to different size order.5.PLC and rotary encoder control, can automatically adjust the slot distance, carton height.6.Equipped with pre-creaser before slotting.7.Can produce large double stitching carton, heaven and earth cover carton8.Equipped with middle knife moving structure.

OPERATION CONTROL

1.Equipped with touch screen control, PLC detection and adjustment, and automatic positioning function.2.Using PLC, rotary encoder and electric button all can adjust the cutting size and carton height. 3.Equipped with emergency stop device to ensure safety.

SLOTTING PHASE ADJUSTMENT1.Equipped with high precision frequency conversion 360 degree speed adjustment, can be positive adjustment and negative adjustment.2.Equipped with Phase zero device, to ensure the consistency of the slot position.CREASING WHEEL1.The creasing wheels surface wear high quality resin, which can avoid the damage of cardboard.2.The lower shaft of the slotting cutter is all provided eccentric sleeve structure to make it compact and accurate.

Die Cutting Unit

OPERATION CONTROL1.Equipped with digital display and PLC and rotary encoder automatic detection function.2.Equipped with emergency stop device to ensure safety.PHASE ADJUSTMENT1.The anvil cushion adjusted up and down by electric form, and can automatically move continuously in axial direction, with each stroke of about 20mm. It can make the rubber sleeve wear uniform, prolong the service life.2.Die cutter is adjusted by electric around 360 degree, and the die cutter shaft can be adjusted ±8mm. DIE-CUTTING CREASING SHAFT1.It is made of seamless steel and it surface is plated with hard chromed. The diameter is φ360mm ,and it carried out dynamic balance calibration.2.The surface is covered with polyurethane rubber mounting using buckle type structure, makes it convenient to replace.3.Die cutting roller adopts independent servo motor drive for speed compensation, and the ordinary carton compensation range is ±3mm.4.Roller adopts mechanical differential structure to make it about automatic traverse, lateral displacement of positive and negative 40mm. It can make the rubber sleeve wear uniform, prolong the service life.5.The clearance of the die cutter rubber roller can be electrically adjusted and equipped with digital display, the adjustment range of 0-12mm.6.Die cutting can be phase adjusted and it will automatic return back to the location, and the cutting wheel will automatically rise, so as to avoid damaging to the rubber pad.PHASE ADJUSTMENT1.Die cutting phase adopts planetary gear structure, which can be used for precise 360 degrees phase adjustment.2.The phase is adjusted by electric, and has digital display and memory function. After adjustment ,it can revert to the original die cutter position.3.Equipped with manual adjustment left and right movement, left and right moving positive and negative 8mm.4.The phase fixing adopts electromagnetic brake mechanism. When the machine platform separates or adjusts the phase, the brake mechanism limits the rotation of the machine and keeps the die cutter position fixed.

Q: Are you a factory or a trading company?

A: We are a direct manufacturer that is located in Dongguang county, Cangzhou city. Welcome to visit our factory! We can also have video call if you'd like an online factory tour

Q: How do you ensure your quality?

A: 1. Trustworthy and long-term cooperative raw material suppliers;2. Skilled&experienced engineer&workers;3. Mature QC system;4. Specially-assigned merchandiser;5. Advanced production workshop

Q: How about your after-sale service?

A: 1. Special after-sale team will be 24/7 online;2. Can guide the installation door-to-door;3. One-year warranty for spare parts.

Our Contact