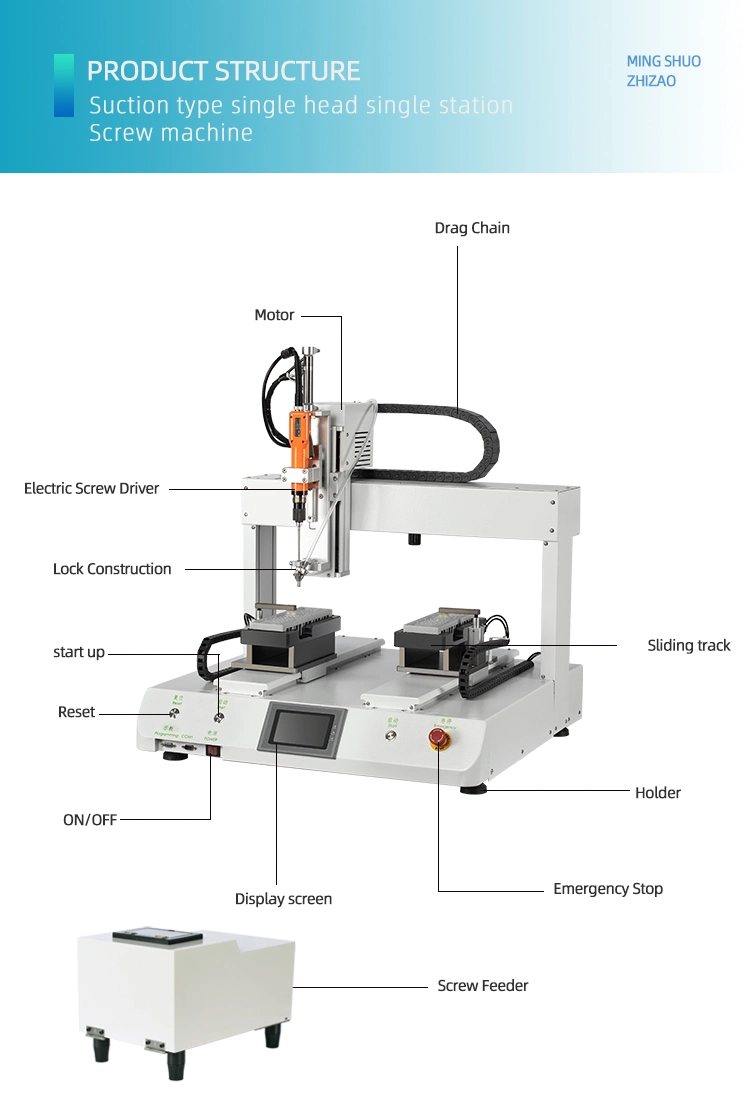

Desktop Screw Blowing Feeding Robotic Fastening Machine with Enclosure and Curtain Sensor/Electric Tool/Automatic Feeder/Fastening Robot

Product Description: Screw Fastening Robot greatly improves the work efficiency and the screw fastening consistency & re

Description

Basic Info

| Model NO. | MS-PC-DS5441-SP |

| Warranty | One Year |

| Transmission Type | Flexible |

| Automatic Production Line | Assembly |

| Certification | CE |

| Automation | Automation |

| Flexible Production | Intelligent Manufacturing |

| Rhythm | Flow Production Line |

| Production Scope | Parts Production Line |

| After-sales Service | One Year |

| Transport Package | Wooden Case |

| Specification | 800x600x700mm |

| Trademark | MS |

| Origin | China |

| HS Code | 8479899990 |

| Production Capacity | 2000sets/Year |

Product Description

Screw Fastening Robot greatly improves the work efficiency and the screw fastening consistency & reliability. With the advanced Teaching Pendant, operators can set up by themselves all the process parameters such as the screw coordinate and screw types, etc. It can adapt to all sorts of difficult screw fastening process and achieve the complete automation.

Features:

- The screws will feed to the screwdriver bit directly one by one through a tube, to achieve extremely fast feeding and screwing.

- The operator can use manual positioning to do the programming. It is highly efficient and very easy to learn the operation.

- With alarm function for fastening missing, untightened screws, worn thread, etc.

- Support auto sensing start operation function.

- With the fixed work table, the working position can be adjusted flexibly.

It is suitable for all kinds of screw fastening process on mobile phones, keyboards, monitors, car accessories, toys, small home electrical appliances, integrated circuits, printed circuit boards, LCD screen, electronic components (such as relays, speakers), etc.

Parameters:

| 1 | Model | CLYY4441 |

| 2 | Feeder mode | Blowing Type |

| 3 | Dimension (L*W*H) (mm) | 700*580*650mm |

| 4 | Weight(kg) | 45 KG |

| 5 | Operation Range (X*Y*Z) (mm) | 380*365*65mm |

| 6 | Screwing time for each screw | 1.0~1.2s/piece |

| 7 | Suitable screw size | M1.5 - M4 (total screw length ≤ 20mm) |

| 8 | Maximum Speed | X,Y 600mm/S, Z 500mm/S |

| 9 | Repeatability Accuracy | X,Y,Z ±0.02mm |

| 10 | Teaching Method | Remote Teaching/Manual Data Input/Optional: LCD Touch Screen |

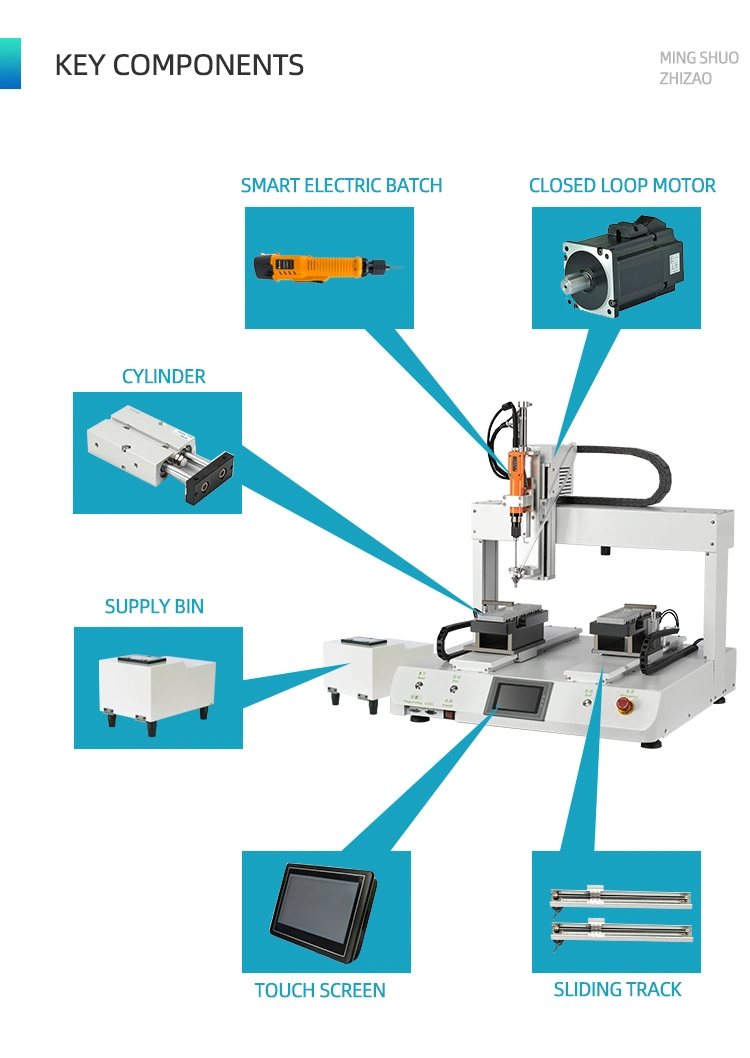

| 11 | Motor system | precision stepper motor |

| 12 | Driving mode | Precision Stepping Motor+Timing belt |

| 13 | Control Panel | Teach pendant (optional:PC or Touch Screen) |

| 14 | Screwdriver brand | Taiwan DG / Japan HIOS |

| 15 | Torque Range | 0.5~15kgf.cm (can be adjusted ) |

| 16 | Tighten efficiency | About 60pcs/min(according to the screw type) |

| 17 | Voltage | AC 110V/220V,50Hz/60Hz |

| 18 | External Interface | USB + RS232 |

| 19 | Power Source | Electricity + Pneumatic |

| 20 | Air pressure requirement | 0.4 to 0.6MPa (4 to 6kg/cm2) as dry air |

| 21 | Working Temperature | 5-40C° |

| 22 | Working Humidity | 20-90% RH |

Our Contact

Send now