Wide Application Mining Plate Apron Feeder

Description

Basic Info

| Model NO. | Apron Feeder-GBZ100-6 |

| Overall Dimension | 7830X3718X980mm |

| Link Joint Width | 1000mm |

| Link Joint Length | 6000mm |

| Link Joint Speed | 0.016~0.05m/S |

| Feeding Size | Less Than or Equal to 450 |

| Capacity | 16.6~50 Cubic Meters/H |

| Motor Power | 15kw |

| out Size | 7830X3718X980mm |

| Weight | 21050kg |

| Transport Package | Standard Export Packing |

| Trademark | HYB |

| Origin | Liaoning, China |

| HS Code | 847490000 |

| Production Capacity | 20 Sets/ Month |

Product Description

Heavy Duty Apron Feeder,is widely used in mining,metallurgy,building materials,coal and other industrial area.It is suitable for short distance transportation for larger piece of material,usually for large concentrator as a continuous,uniform and adjustable storage warehouse to primary crushing equipment.The feeding material can also be used to a short distance conveying,especially when the apron feeder installation at the bottom of the hopper,the pressure of the material directly grained materials.It can complete the heavy work in the bad environment,to the material granularity,the composition change,the temperature,the viscosity,the frost,the rain snow influence or the frozen material all has the relatively big adaptability.General horizontal installation,or tilt installation,the maximum inclination is 25°. The apron feeder is a reliable feeding method for when the material to be conveyed is lumpy, abrasive, heavy, high temperature. it is a feeding solution more robust than a traditional belt feeder is required. Apron feeders are designed to feed material at a desired handling capacity to downstream equipment. The conveyed material is on many overlapping pans attached to multiple strands of a heavy tractor crawler-type chain.

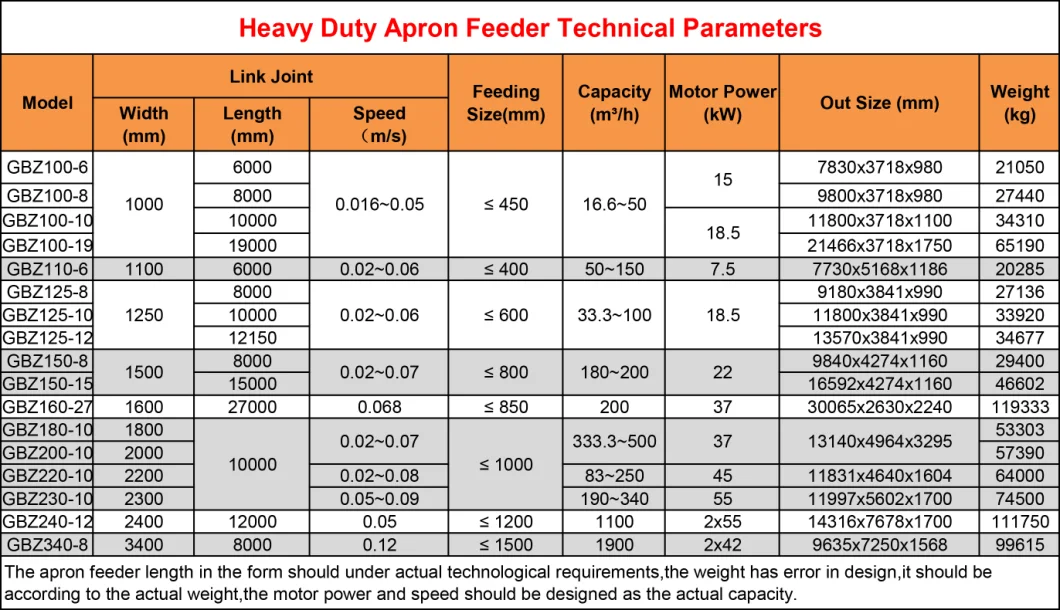

Product Parameters

Company Profile

Shenyang Huayue Brilliant Machinery&Equipment is a manufacturer of a wide variety of Mining equipment, which we provide to customers all over the world. Our primary products include: Jaw Crusher, Cone Crusher, Ball Mill, Feeding Equipment, Vibrating Screen, and their related spare parts. As a direct manufacturer and dealer of mining equipment with 10 years of experience in this field, in addition to our professional technology support, HYB is able to offer the most reliable, high-quality mining equipment to our customers. Our premium products are widely used in various fields, such as: the mining, metallurgy, highway, railway, and chemical industries. Our Crushers are widely used for stone crushing in the fields of mining, metallurgy, and building material;Ball Mill are widely used for Gold Mining, Copper Mining and so on. and our Vibrating Screens are sought after for dry and wet screening in the coal, mining, quarry, and other industries. We have a strict quality control system in place throughout the entire production process, so our products are all of the highest quality and reliability. As a result, our mining equipment and other products are popular in markets all over the world. Our goal is to provide minining equipment of excellent quality and reliability, in order to establish a reputation and relationship with our customers which will keep them customers for life. We also offer OEM service upon request. If you have a need for any mining equipment, or related spare parts, please feel free to contact us. We are dedicated to serving each of our customers to their complete satisfaction.Our Advantages

MAIN COMPONENT:

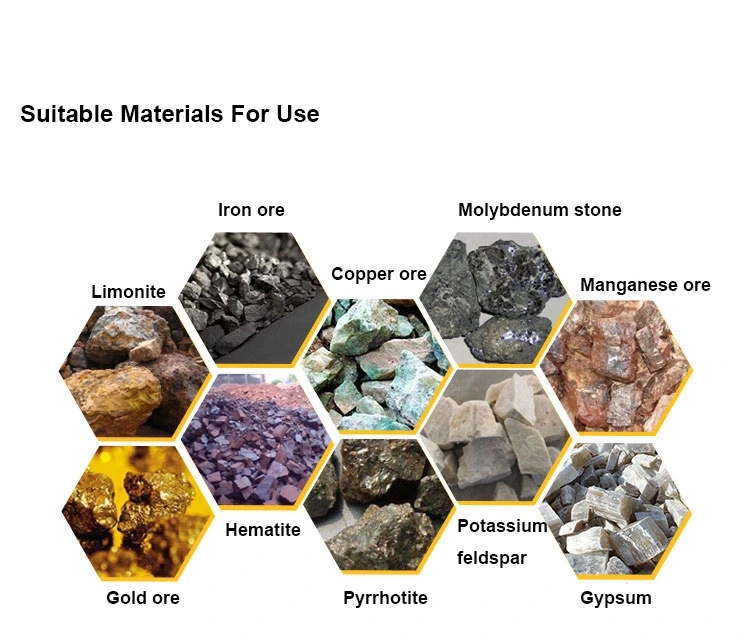

Features: 1.Standard heavy-duty ribbed pans prevent excessive deflection under high-impact loading & severely abrasive working conditions. 2. Cast segmental track chain bolted to heavy steel hubs keyed to oversized front drive shaft. 3. Standard crawler-type under carriage parts have a long service life.4. Rugged steel support frame with impact rails to limit pans deflection, thus eliminating permanent bending of the pans. 5. The heavy-duty design delivers high availability, ease of operation, low maintenance and operational costs and greater profits. Advantages: 1. The apron feeder is widely used for conveying metal, limestone, gold ore and construction waste, gypsum etc,.2. It can bear big pressure under large silo or loader. 3. The speed can be adjusted by frequency conversion control cabinet. 4.Including the feed trough, to prevent the material leakage. 5. Thickness of plate is from 8mm to 20mm. 6. Can be customized.

FAQ

Q1: How to choose the suitable model ?

A: Please confirm the following information :

1. what kind of stone do you want to crush ?Such as granite ? limestone ?

2. what's the size of your stone before crush ? how many inch or mm ?

3. what's your requirements of final product size ? how many inch or mm ?

4. what's your requirements of production capacity ? how many ton per hour ?Q2. How long is the warranty? Does your company supply related spare parts?

A: The crusher equipment is warranted for one year. And we provide spare parts at reasonable price.

Q3: How long is the delivery time?

A: Generally it takes one week if the goods are in stock. Otherwise it needs 15-20 days, and it also depends on the ordered quantity.

Prev: High Frequency Dewatering Machine Vibrating Screen

Next: Yz Series Xxnx Linear Vibrate Sieve Large Capacity Linear Vibrating Screen

Our Contact