Ss 304 Sifter Shaker Separator Grain Sieve Machine Powder Rotary Vibrating Screen for Food

Description

Basic Info

| Model NO. | SY-800 |

| Usage | Lightweight Fine Shaker |

| Works | Rotary Vane Shaker |

| Object | Food Processing |

| Shaft Number | Single |

| Running Track | Circular Vibrating Screen |

| Supporting Device | Coil Spring |

| Warranty | 1 Year |

| Customized | Customized |

| Condition | New |

| After-sales Service | Free Spare Parts, Online Support, Video Technical |

| Phase | Three or Single |

| Material | SUS 304/316 or Carbon Steel or as Customer Request |

| Mesh Type | Woven Wire or Punching Hole |

| Power | 0.25-3(Kw) |

| Deck | 1-5 Decks |

| Certification | ISO9001:2008/CE |

| Capacity | 100kg-10tons/Hour |

| Cleaning System | Bouncing Ball |

| Voltage | 220V/380V/415V |

| Installation | Technical Guidance |

| Transport Package | Standard Export Plywood Case |

| Specification | 400-2000mm |

| Trademark | sanyuantang |

| Origin | Xinxiang, Henan |

| HS Code | 847410000 |

Packaging & Delivery

Package size per unit product 110.00cm * 117.00cm * 139.00cm Gross weight per unit product 310.000kgProduct Description

SS 304 Separator Powder Rotary Vibrating Screen Grain Sieve Machine Sifter Shaker for Food

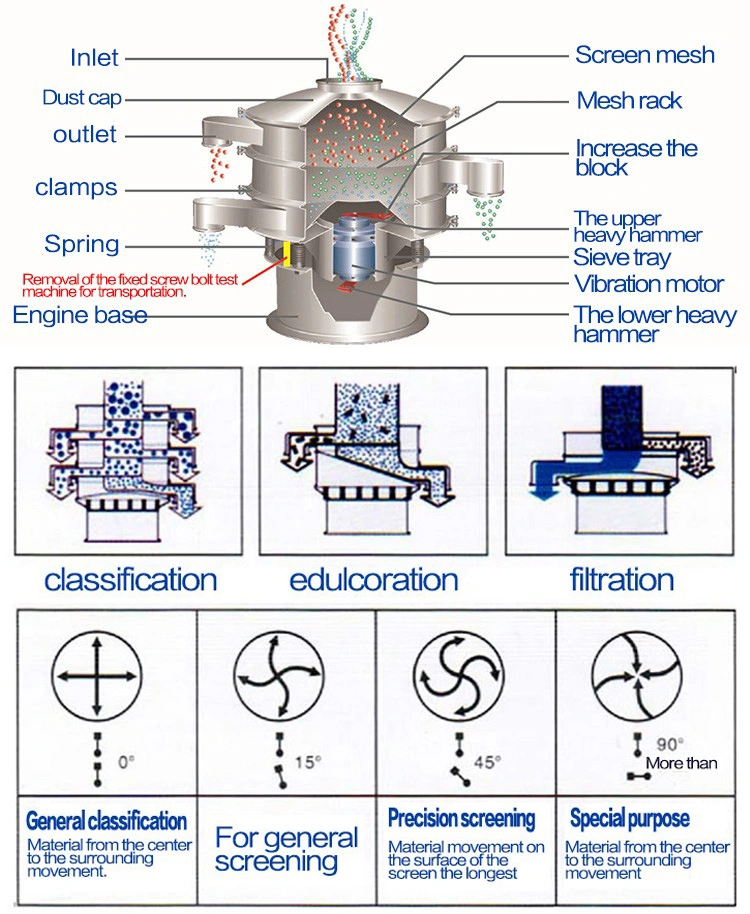

Product Principle

Rotary Vibrating Screen is a high-precision powder griddle, low noise, high efficiency, quick changer takes 3-5 minutes, totally enclosed structure, for grain, flour, mucus and other materials screening filter. Rotary Vibrating Screen is a motor for vertical excitation source, the motor and lower eccentric weight installed at both ends of the motor rotary motion into a horizontal, vertical, inclined three elementary motions, then the movement passed to the screen surface . Adjust the upper and lower ends of the phase angle, the material can change the trajectory of the screen surface.

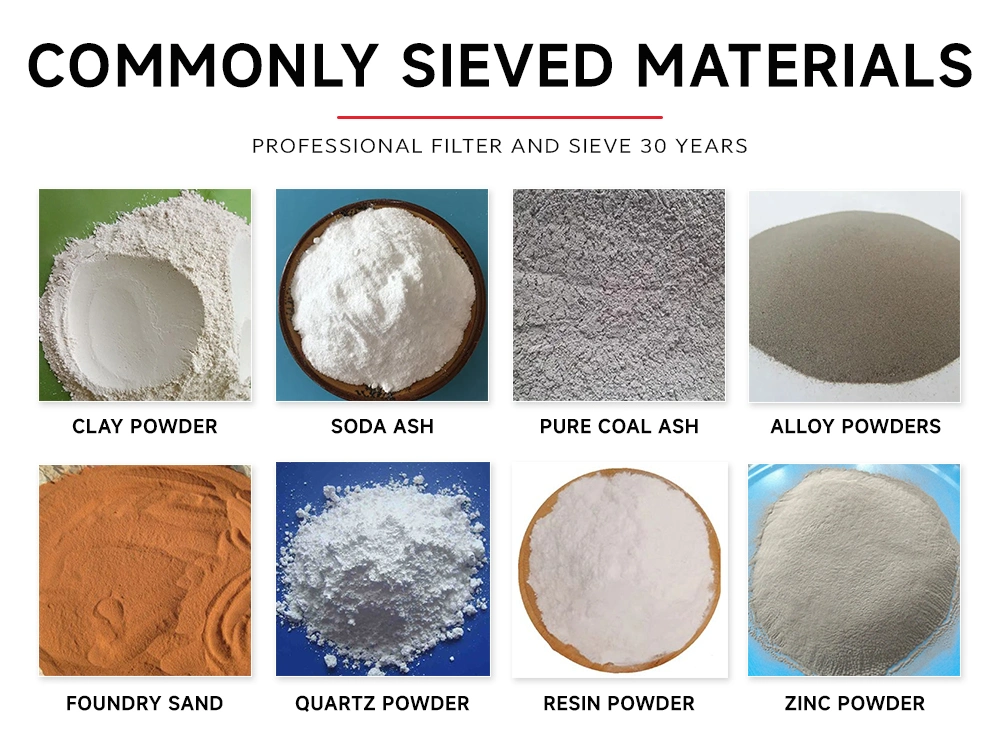

ApplicationThe product is applicable to any powder, granule, liquid screening and filtering of the industry. SY series rotary vibration screen is widely used in chemical industry, medicine powder, liquid, paint, pigments, cosmetics, oil, resin, ceramic slurry, clay slurry, lime, refractory powder at the end, magnetic powder, polishing powder, fruit juice, beverage, sugar, salt, MSG, spices, milk powder, starch, flour, rice flour, carbon powder, graphite powder, manganese powder, lithium carbonate, help solvents, fire extinguishing agents, as well as the environmental protection industry wastewater, wastewater treatment process of screening, filtering.

Technical parameter

| Model | Effective diameter For sieving surface(mm) | Screen size | Layer | Powder(KW) | |

| Vibration motor | Common motor | ||||

| SY-400 | 380 | 2-500 mesh | 1-5 | 0.18 | 0.25 |

| SY-600 | 580 | 2-500 mesh | 1-5 | 0.25 | 0.55 |

| SY-800 | 780 | 2-500 mesh | 1-5 | 0.55 | 0.75 |

| SY-1000 | 970 | 2-500 mesh | 1-5 | 1.1 | 1.1 |

| SY-1200 | 1170 | 2-500 mesh | 1-5 | 1.1 | 1.5 |

| SY-1500 | 1470 | 2-500 mesh | 1-5 | 1.5 | 2.2 |

| SY-1800 | 1770 | 2-500 mesh | 1-5 | 4 | 3.0 |

Product Shows

Our Services

All produts purchased in our company are guaranteed to keep in good repair for one year. If quality problems happen in guarantee period, our company will maintain for free.

a, Before sending the machine, we will test and adjust, so you can use directly when you get it.b, Operation video & instruction will be sent to clients, to help them use the machines better.

Additionally, our company provides technical support and fittings for life. After-sales service isn't restricted by time and we will solve your problems in time. If you are caught in some problems when using our products, welcome to contact us at any time.

a, Any problems occur while using, professional advice will be offered.

b, All kinds of frequently used parts are supplied all the year round.

Packaging & Shipping

Export standard plywood package are supplied with well packed. we can make the packages according to customer's request. Sea packages or Air packages are both available.Usually to ship machine by sea way.

Company Information

Xinxiang Sanyuantang Machine.ISO9001 certified enterprise.Our company is located in XINXIANG CITY HENAN PROVINCE CHINA,We are one of leading manufacturer who specialize. At present, the main range of products include kinds of series of Vibrating Screen,Conveyor Equipment,Honey Processing Machine,etc. We have advanced manufacture equipment, abundant technology power, complete testing measures, strict management system and favorable corporation credit-standing.

Our products1.Vibrating screening;2.Conveyor equipment;3.Honey processing machine;4.Related equipments and spare parts.

FAQ

Q: What are you mainly specilized in?

A: Our company is a professional manufacture of vibrating screen sifter equipments(like rotary vibrating screen,ultrasonic sieving machine,linear vibrating screen,test sieve machine,trumbler screem,drum screen,direct discharge screen,airflow sieving machine,450 filter machine and so on);conveying equipment (like screw conveyor,bucket elevator,vertical vibration elevator and so on);honey machine(honey processing machine,honey filling machine)Q:What's your after-sales services?

A: 24 hours service online,you can tell your trouble any time

Q:What is the MOQ of our products?

A:Usually 1 set

Q:What is the payment terms?A. Usually use T/T,but Western Union is also available

Q:What's your delivery time?

A:Ususlly 7-10 working days,if the order is large,the time should be longer

Q:What's the advantage compared to other suppliers?

A:We are a factory,We have business directly with our customers,there isn't any link between customers,so we can offer competitive price for you.Contact Us

Our Contact