Self Cleaning Square Swing Gyratory Vibrating Screen for Sand

Description

Basic Info

| Shaft Number | Single |

| Running Track | Linear Vibrating Screen |

| Supporting Device | Plate Spring |

| Warranty | 1 Year |

| Customized | Customized |

| Condition | New |

| After-sales Service | Perfect After-Sales Service and Use Guidance |

| Transport Package | Standard Export Plywood Case |

| Specification | Customizable |

| Trademark | TFZD |

| Origin | Xinxaing, Henan |

| HS Code | 8474100000 |

| Production Capacity | 2000pieces/Years |

Product Description

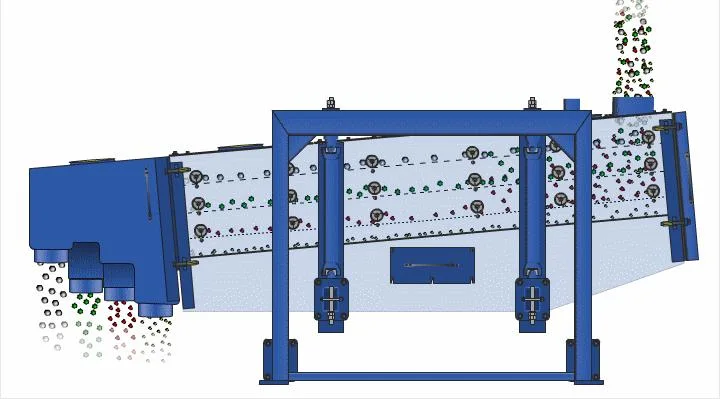

Self-Cleaning Square Swing Gyratory Vibrating Screen for SandProduct introduction

A square swing screen is a kind of artificial screening equipment with a horizontal circular rotation of the screen body. The device can change the number and combination of various network layers according to customer requirements. Because of its stable working state and no up and down vibration during operation, the product has the technical characteristics of large output, high precision, long screen life, low failure rate, etc. Compared with the traditional screen machine, the output, and fineness are greatly improved.

Working principle

The working principle of a square swing screen is that the eccentric force generated by the internal vibrator drives the screen body to move. The materials can enter the grid evenly and quickly through the feeder at the feed inlet. Through the swing motion of the screen machine, the materials can quickly spread on the screen surface and move forward against the screen mesh. The screen body has an inclined angle of 4.5 ° - 5.5 ° with the horizontal plane so that the materials smaller than the mesh can quickly pass through the screen mesh to the lower screen surface. The materials are screened by continuous multi-layer screening, graded from multiple outlets, and designed so that the materials with the same mesh number can be gathered at one outlet to complete screening.

Product Features

1. Reasonable design, simple structure, and stable operation;

2. The screen has a long service life, high screening accuracy, convenient and quick screen replacement, and silica gel balls are placed in each screen grid, with the function of screen cleaning, which can improve the screening efficiency;

3. The exciter unit is an integral box structure, which has the technical characteristics of simplicity, rationality, firmness, stable design, and even transmission of exciting force.

4. Good sealing effect, low noise, no dust, and improved workshop working environment.

Technical parameters

| Model | Screen Size(m) | Screening area(m²) | Power(KW) | Screen surface inclination(°) | Rotation frequencyr/min | Screen box stroke(mm) | Number of layers |

| FYB 1036 | 1.0*3.6 | 3-27 | 3 | 5±3 | 180-260 | 25-60 | 1-9 |

| FYB 1236 | 1.2*3.6 | 4-36 | 5 | 5±3 | 180-260 | 25-60 | 1-9 |

| FYB 1536 | 1.5*3.6 | 5-45 | 5.5 | 5±3 | 180-260 | 25-60 | 1-9 |

| FYB 2040 | 2.0*4.0 | 8-72 | 7.5 | 5±3 | 180-260 | 25-60 | 1-9 |

Applicable industries

Chemical industry: resin powder, pigment, washing powder, micro powder, paint, soda ash, lemon powder, rubber, plastic, etc.

Abrasives, ceramic industry: alumina, quartz sand, mud, sprayed soil particles, etc.

Food industry: sugar, salt, alkali, monosodium glutamate, milk powder, soy milk, yeast, fruit juice, soy sauce, vinegar, etc.

Paper industry: coating paint, clay mud, black and white liquid, waste liquid, papermaking liquid, wastewater recycling, etc.

Metallurgical industry: titanium oxide, zinc oxide, electromagnetic materials, metal powder, electrode powder, etc.

Pharmaceutical industry: Chinese medicine powder, Chinese medicine liquid, Western medicine powder, Western medicine liquid, Chinese and Western medicine granules, etc.

Environmental protection: garbage, human and animal excrement, urine, waste oil, food wastewater, wastewater processing, etc.

some small equipment or parts will be made from here.

There are cranes, laser cutting machines, electric welding machines, platen machines, angle grinders, polishing machines, forklifts, and other equipment.Here is our outdoor operation platform.

We often produce and assemble large machines here.

There are electric welding machines, polishing machines, large cranes, and forklifts.Packaging & Shipping

After you place the order and pay the deposit, we will start to arrange the production and contact the ocean freight transportation agency to reserve the position. Two days before the end of production, you need to complete the final payment. Then, we inform the ocean cargo transportation agent company that it is ready to come to the factory to pull the goods to the port. On the day of delivery, we will send the customer the factory video and pictures, and mark the corresponding English name of each product and product parts with a marker to prevent the customer from not knowing what each part is after receiving the goods. At the same time, we will put the English version of the product instructions in the cargo box. We generally select freight forwarders with preferential prices for customers to deliver goods for you. The shipping method can be FOB or CIF. You can also choose EXW, and then contact the goods agent company yourself.

Customer visit Company Profile

Our company has taken the lead in passing ISO9001 quality system certification, CE certification, and SGS certification, and was awarded Henan High tech Enterprise in 2022.

We can provide customized products, services, and solutions to meet the needs of customers in different industries, and have established long-term partnerships with customers from Southeast Asia, the Middle East, Africa, South America, Oceania, and other countries.

The company is located in Xinxiang City, Henan Province, China. It is only an hour and a half drive from Xinzheng International Airport. We provide a free shuttle service. We sincerely invite foreign friends to visit our company and have face-to-face exchanges to jointly promote development.CertificationsFAQ

1. Who are we?

Our headquarters is located in Henan, China, and our factory was established in 2002. At present, there are more than 100 workers, technical engineers, foreign trade sales personnel, and administrative personnel. The factory covers an area of more than 2000 square kilometers and is mainly engaged in vibrating screening and conveying and feeding equipment.

2. How do we guarantee the quality?

Always provide pre-production samples before mass production; always conduct a final inspection before shipment.

3. What can you buy from us?

You can purchase a vibrating screen, roller screens, rotary screens, vacuum conveyors, mixers, and customized vibrating machinery and conveying equipment in our factory.

4. What are our strengths?

As one of the old enterprises in the screening industry, Tianfeng has provided many screening equipment and systems at home and abroad. Mass production, rapid delivery, stable quality, affordable price, and excellent after-sales service have become the symbols of Tianfeng.

5. What services can we provide?

Accepted delivery conditions: FOB, CFR, CIF, EXW, CIP, FCA, CPT, DDP, express;

Accepted payment currency: USD, EUR, RMB;

Type of payment accepted: telegraphic transfer, letter of credit, express remittance, credit card, PayPal, Western Union remittance, cash, custody;

Oral: English, Chinese, French.

6. What information do we need to help you choose a perfect machine?

-Name and characteristics of raw materials.

-Purpose of use: remove impurities, filter, and grade.

-Processing capacity: kg/h, L/h.

-Raw material size: (mesh or mm).

-How many floors do you need?

-Voltage, frequency, phase (single-phase or three-phase) Note: You'd better send us the relevant pictures or materials you want to filter, which can ensure that we recommend the appropriate machine for you.

Prev: Continuous Plastic Bag Sealing Machine with Conveyor Belt

Next: Mining Equipment 4 Decks Single Deck Vibrating Screen Fine Sand Stone Vibrate Screen

Our Contact