Rubber PVC Conveyor Belt Splicing Joint Press Machine

Description

Basic Info

| Model NO. | HK Series |

| Warranty | 2 Years |

| Control Type | PLC |

| Automatic Grade | Automatic |

| Power Source | Electric |

| Type | Rubber Vulcanizing Machine |

| Simple Structure | Easy Operation |

| Color | Customized |

| Certification | Ce/SGS/ISO |

| Delivery Time | Shipped in 7days After Payment |

| Voltage | 220V,240V,380V,400V,415V,440V |

| Safety Device | Equipped |

| Using Life | 15 Years |

| Extrusion Quality | Excellent |

| Application | Rubber Belt Splicing |

| Material | Rubber PVC PU |

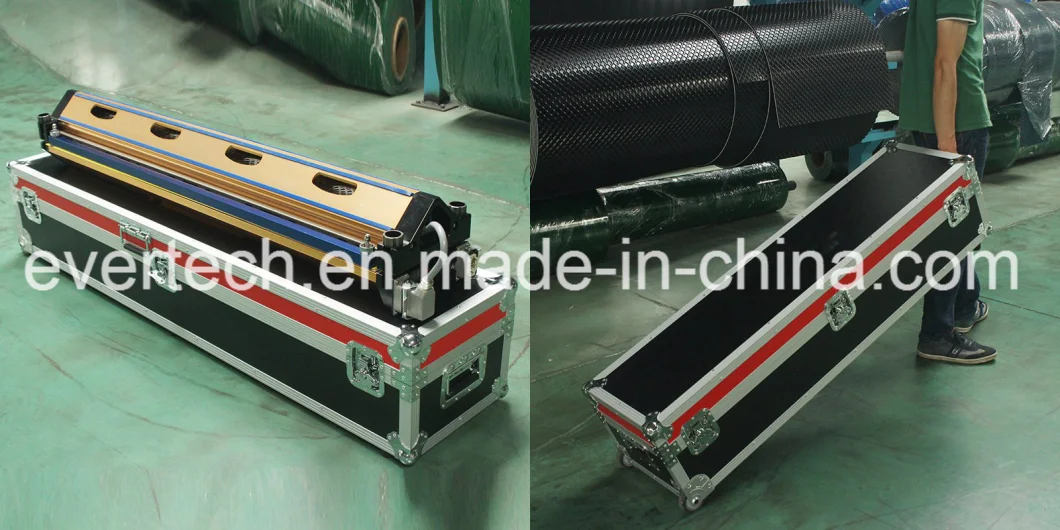

| Transport Package | Nude Packing or According to Customers Needs |

| Specification | HK Series |

| Trademark | HK |

| Origin | Qingdao, China |

| HS Code | 84778000 |

| Production Capacity | 100sets/ Month |

Product Description

Rubber PVC conveyor belt splicing joint press machine

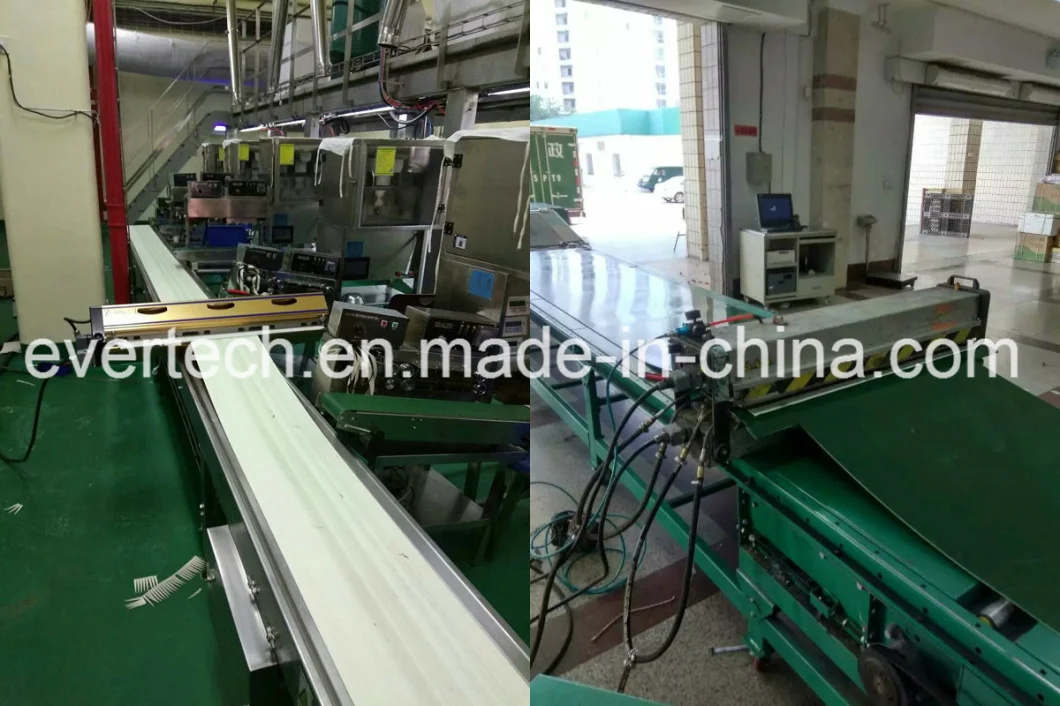

1. application For the vulcanization and splicing of nylon conveyor belt, ep conveyor belt, steel cord belt. 1. Features:1) Vulcanization pressure: 1.5Mpa; (217Psi; 15kg/cm2)2) Vulcanization temperature: 145 Celsius degree; (293 Fahrenheit equals)3) Difference in surface temperature of vulcanized plate: ± 5 Celsius degree; (41 Fahrenheit equals)4) Calefactive time (at normal temperature to 145 Celsius degree): ≤30 mins;5) Power supply voltage: 220V to660 v; 50/60 Hz; 3Phase;6) Output power of Electronic Control Box: 36 KW;7) Temperature adjustment range: 0 to 200 Celsius degree; (0 to 392 Fahrenheit equals)8) Timing adjustment range: 0 to 99 min;9) After the pressurization of 0.8MPa (=116Psi =8kg/cm2),10) The gap between upper and lower heating plate is not more than 0.4 mm.11) Applicable belt width: From 650-2600mm (26" to 102"). 2. Technical Parameters:

| Tool Specifications | HK300 | HK600 | HK900 | HK1200 | HK1500 | HK1800 | HK2100 |

| Effective length | 305 mm | 610 mm | 914 mm | 1219mm | 1524mm | 1829mm | 2360mm |

| Effective width | 130 mm | 130 mm | 130 mm | 130mm | 130mm | 130mm | 130mm |

| Weight lower part | 10 kg | 16 kg | 20 kg | 28.5KG | 30KG | 32KG | 36kg |

| Weight upper part | 11 kg | 13 kg | 18 kg | 25.5KG | 30KG | 42KG | 55kg |

| Weitht Bumper | / | / | / | / | / | 37kg | 43kg |

| Total weight | 21 kg | 30 kg | 38 kg | 54KG | 62KG | 76KG | 134kg |

| Length | 505 mm | 805 mm | 1105 mm | 1405mm | 1705mm | 2005mm | 2360mm |

| Overall Height | 220 mm | 225 mm | 225 mm | 225mm | 225mm | 225mm | 255mm |

| Overall Width | 250mm | 250mm | 250mm | 250mm | 250mm | 255mm | 255mm |

| Max. pressure | 2Bar | 2Bar | 2 Bar | 2bar | 2bar | 2bar | 2bar |

| Max. temperature | 200 ˚C | 200 ˚C | 200 ˚C | 200 ˚C | 200 ˚C | 200 ˚C | 200 ˚C |

| Dimensions for transport (mm) | 712 x 352 x280 | 1012 x 352 x 280 | 1312 x 352 x 280 | 1612 x 352 x 280 | 1912 x 352 x 280 | 2212*352*300 | 2567*352*300 |

| Weight for transport | 26 kg | 35 kg | 43 kg | 84KG | 96KG | 176KG | 219KG |

| Power | 1.6KW | 2.8KW | 4KW | 5.2KW | 6.4KW | 7.6KW | 8.8KW |

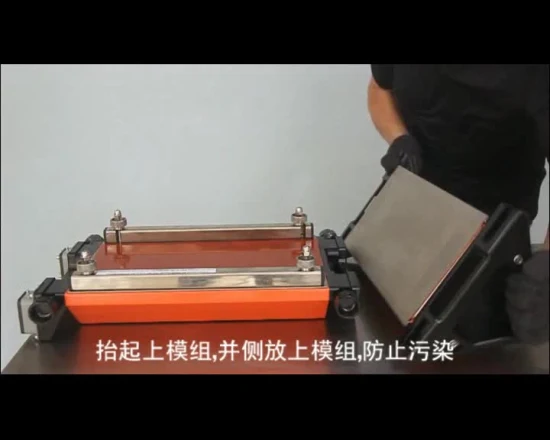

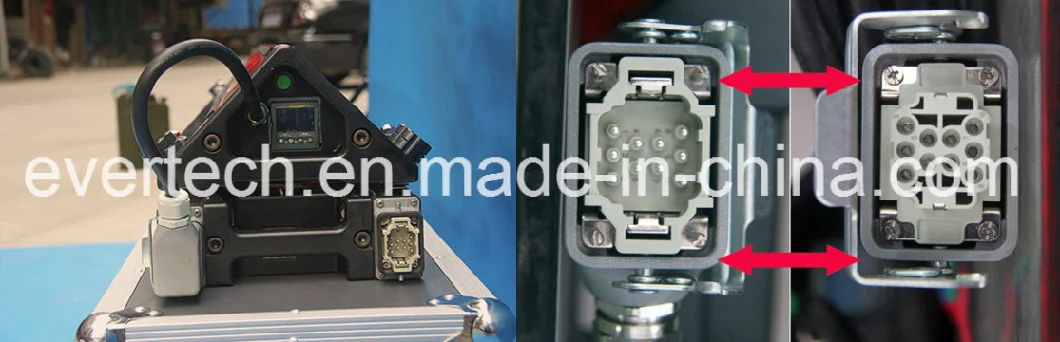

Fast Splicing: include heating time and cooling time, no more than 12 mins.Faster cooling:Anodizing , cooling time shorter and surface keep for long time.All in one design: The press has an integrated air-cooling system and also air compresor inside. To ensures that the belt is quickly cooled down and auto press on, without water pump or aditional air compresor.Easy to use and assemble, how to operate pls freely to refer to below video.Light weightReliable and automatic Temperature Control with time control (in one meter, also you can set by yourself).Air pressure controller (set the air pressure and display the current pressure),made in Germany.Voltage: 220V or 380V, if special voltage pls freely to inform us.

Air freight

Before order, or send inquiry to us, pls include below informaiton: 1.Belt max width2.Heating platen length3.what kind of press, normal type or 2pcs type.4.Working pressure5.Working voltage6.Any other special requirements, for example like 2 sets small heating platens for one big press etc. thanks.

Our Service ♦ Our engineers can design target machines for customers and send them the drawing to confirm. We are always on the side of saving your cost. ♦ In the process of production, we will take photos and send to customers for their track the progress. ♦ Documents such as packing list, commercial invoice, and bill of lading etc. will be sent after the delivery. ♦ We could supply free English foundation DWG, installation drawing, user guide, maintenance manual and part drawing. ♦ We supply overseas engineer service and help to train your workers to operate the machine.

Our Contact