Engine Block Cylinder Head Wire Mesh Conveyor Belt Shot Blasting Machine

1. Description Wire mesh belt shot blasting machine is mainly used for automobile,aerospace railway and other machine ma

Description

Basic Info

| Model NO. | WMB |

| Automation | Automatic |

| Certification | CE, CB, ETL, RoHS, UR |

| Feature | Non-Toxic |

| Condition | New |

| Customized | Customized |

| Running Speed | 2-6m/Min |

| Motor Brand | Siemens |

| Key Selling Points | Long Service Life |

| Blast Chamber | Mn13 |

| Dust Collector | Filtering Cartridge |

| PLC | Seimens |

| Blast Wheel | Low Noise Level |

| Color | Customers Requirement |

| Blast Wheel Layout | 3-D Dynamic Simulation Design |

| Filters Material | Donaldson |

| Frequency Converter | Omron |

| Transport Package | 20FT/40FT Container |

| Specification | Customized |

| Trademark | ET |

| Origin | Qingdao, China |

| HS Code | 8460909000 |

| Production Capacity | 30sets/Month |

Product Description

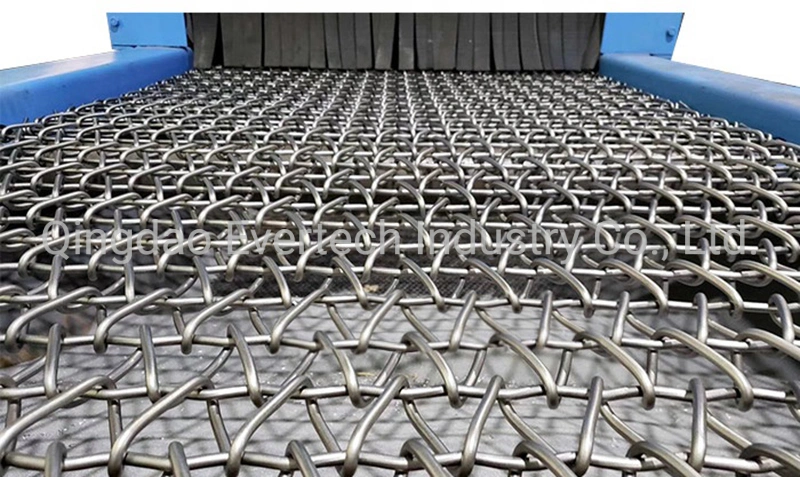

1. DescriptionWire mesh belt shot blasting machine is mainly used for automobile,aerospace railway and other machine manufacturing industry,especially suitable for the surface shot blasting of the thin-walled iron castings or aluminium castings and other small parts.It can be used for mechanical parts shot blasting strengthen.Wire Mesh Belt Shot Blasting Machine will have mesh Conveyor System, Blowing Sand System, Vertical Screw Conveyer, Blasting Chamber, Blast Wheel, Bucket Elevator,Screw Conveyer, Separator, Maintenance Platform & Ladder, Providing Sand System, and soon on.

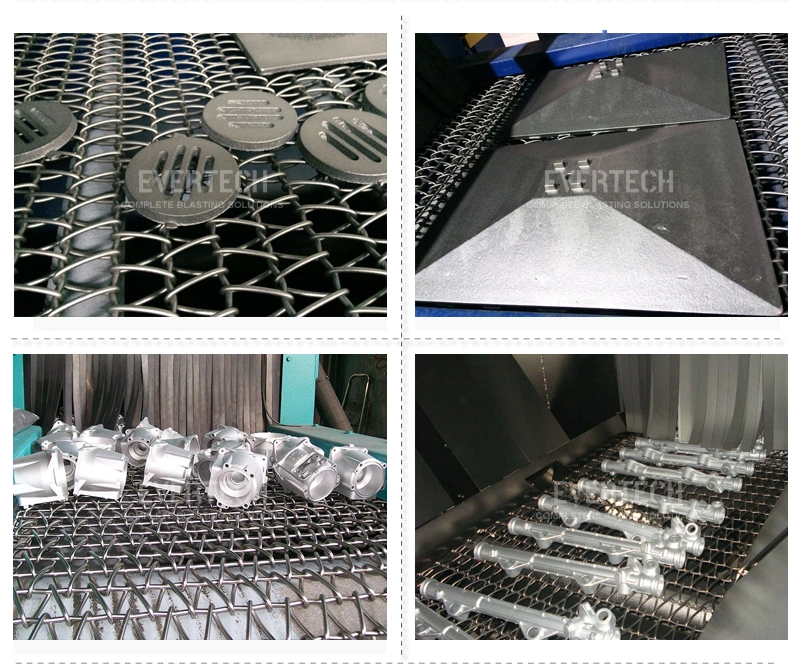

2. Applications

* Aluminum die-castings and alloys (automotive, alimentary, furnishing, lighting, telecommunications, electric tools fields,etc.) * Oxygen-flame cutting parts * Cast iron castings * steel pressing piece * Brass molded pieces

3. Design and Sequence of Operations

* Parts placed on the wire mesh belt conveyor continuously pass through abrasive tight entry vestibule into the blast chamber. * The quantity and placement of the blast wheels coupled with the blast wheel horsepower determine the cleaning capacity and production capabilities of the machine. Blast wheels ensure complete coverage and cleaning of every angle. * The parts are blast cleaned passing through the blast chamber and then exit through the series of seals in the egress vestibule.

4. Basic parameters

| Item | WMB600 | WMB800 | WMB1000 | WMB1200 | WMB1500 |

| Effective cleaning width (mm) | 600 | 800 | 1000 | 1200 | 1500 |

| Dimension of inlet opening(mm) | 600*400 | 800*500 | 1000*500 | 1200*600 | 1500*600 |

| Number of wheels | 4 | 4 | 4/8 | 4/8 | 4/8 |

| Wheel motor power (kW) | 7.5 | 11 | 11/15 | 11/15 | 11/15 |

| Foundations | No | No | No | No | Yes |

| Weight (T) | 20 | 20.4 | 33 | 41 | 53.2 |

Frequently Asked Questions

Q1: How do I get the best price?A: As you may know, the different type of blasting machine apply to the different price.Q2: What machine suits me best?

A: Different workpieces and the different model apply to the different machine.Please tell us what's kind of workpieces need to blast cleaning?And what's MAX size of the workpieces ?Then we will recommand the most suitable model and the best price for you. Q3: In case of failure,how to do?

A: Call us----our enginners are online for 24-hours,and ready to serve you.Replacement of damaged parts for free---For more information,please contact usQ4: Are you trading company or manufacturer ?

A: We are factory.Q5: How long is your delivery time?

A: Generally it is a week days if the goods are in stock. or it is 15 working days if the goods are not in stock, it is according to quantity.Q6: How many people are needed to run the Evertech's shot blasting machine?

A: For Evertech's standard blasting unit, one people will be enough. But for the custom complex production line integrated with shot blaster, the number of operators is varied according to the other accessory equipment and the whole line automaticity.

Q7: What does it cost to operate?

A: The highly efficient turbines require much less power that competitor's shot blast machines. Including abrasive consumption, power consumption and maintenance, the total operating cost averages from $5- $20 per hour. When comparing this to your current methods, keep in mind that the auto shot blasting machine is at least 4 to 5 times as productive as manual cleaning and only one operator is required to load and run the machine while it is working. Labor costs are much lower, plus you will have a huge amount of extra capacity for cleaning.Q8: What utilities are needed to run the blasting machine?

A: The electrical system runs on three-phase input and a transformer will be provided for your supply voltage if required. Clean and dry compressed air supply is also needed. Contact With US

My friend, if you are interested in our products, our company and factory, you can contact us right at now! our beautiful goodsalesman will give you the most sincere service and the most satisfactory answer!

Looking forward to your consultations!

Prev: Hot New CE Approved Tube Tubular Spiral Auger Cement Screw Conveyor Price

Next: Jz CE 1-30t/H Tlss Tubular Screw Feeder Grain Spiral Conveyor Screw Transporter Screw Conveyor

Our Contact

Send now