Energy Saving a+++ Grade Favorable Price Walking Conveyor Belt

Product description Energy Saving A+++ Grade Favorable Price Walking Conveyor Belt Mode: M1511 In Busy Cities, Supermark

Description

Basic Info

| Model NO. | M1511 |

| Type | Step Type |

| Slope Angle | 12° |

| Speed | 0.5M/S |

| Nominal Width | 1000mm |

| Drive Mode | AC |

| Use of Occasions | Indoor Type |

| Handrail Decoration | Full Transparent |

| Control Type | Microcomputer Control |

| Railing Form | EX-EN |

| Step Road Linetype | Linear |

| Moving Sidewalk | Indoor Tytp |

| Usage | Supermarket, Airport |

| Energy Saving Grade | a+++ |

| Moving Walk Certificate | CE |

| Moving Walk Standard | En115-1:2008+A1:2010 |

| Moving Walk Truss Welding | En 1090-1:2009+A1:2011 |

| Moving Walk Degree | 0, 6, 10, 11, 12 |

| Step Width | 800~`1400mm |

| Running Mode | Single Speed up &Down Reversible |

| Warranty | 18 Months After Delivery |

| Transport Package | Standard Export Packing |

| Specification | EN115, GB16899-2011 |

| Trademark | SYNEY or OEM |

| Origin | Zhejiang, China |

| HS Code | 8428400000 |

| Production Capacity | 5000 Sets/ Year |

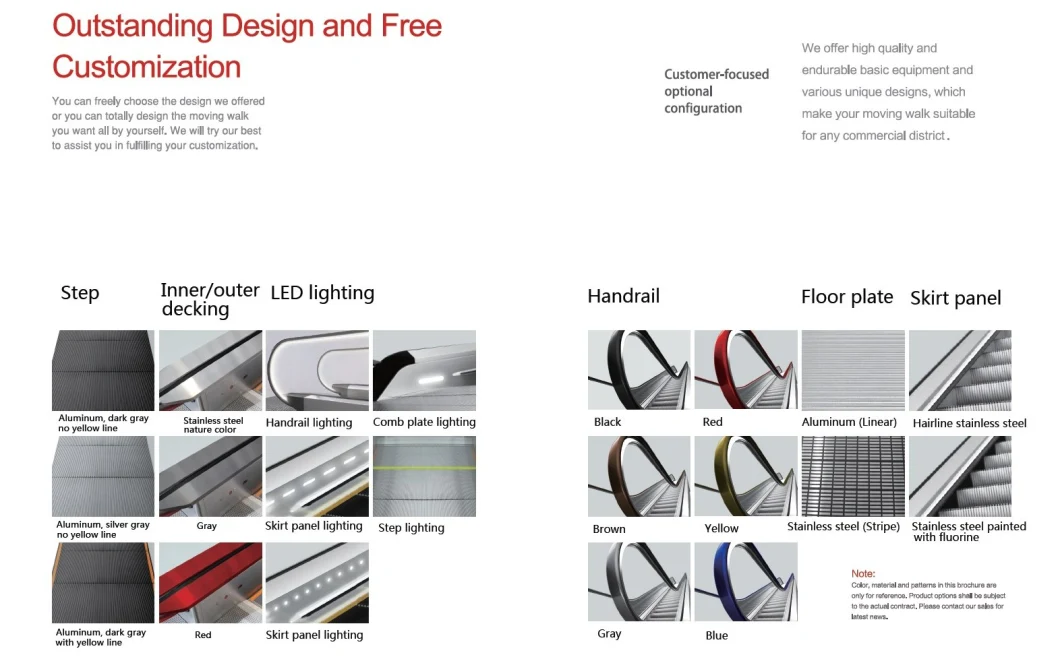

Product Description

Energy Saving A+++ Grade Favorable Price Walking Conveyor BeltMode: M1511

In Busy Cities, Supermarkets and Shopping Malls, Where People Gatherd, Broadly Spread Moving Walks, Creating a Space Full of Imagination, Drawing Splendid Lines Which Link Every Flowing Sights. Safe, Comfortable and Beautiful, Moving Walks Give People a Leisure Time.

| Moving walk | Moving walkway, travelator, passenger conveyor, sidewalk, autowalk |

| Span Length | L≤105000mm |

| Step Width | 800mm, 1000mm, 1200mm, 1400mm |

| Inclined Degree | 0°, 10°, 11°, 12° |

| Speed | 0.5m/s, 0.65m/s |

| Noise | ≤65dB |

| Vibration | ≤35cm/s² |

| Running | Single speed up &down reversible |

| Delivery | 40ft high container |

| Power Supply | Power 380V , 50Hz Three Phase Five Wire System Lighting 220V, single phase |

| Energy Saving Function | VVVF, Auto start stop |

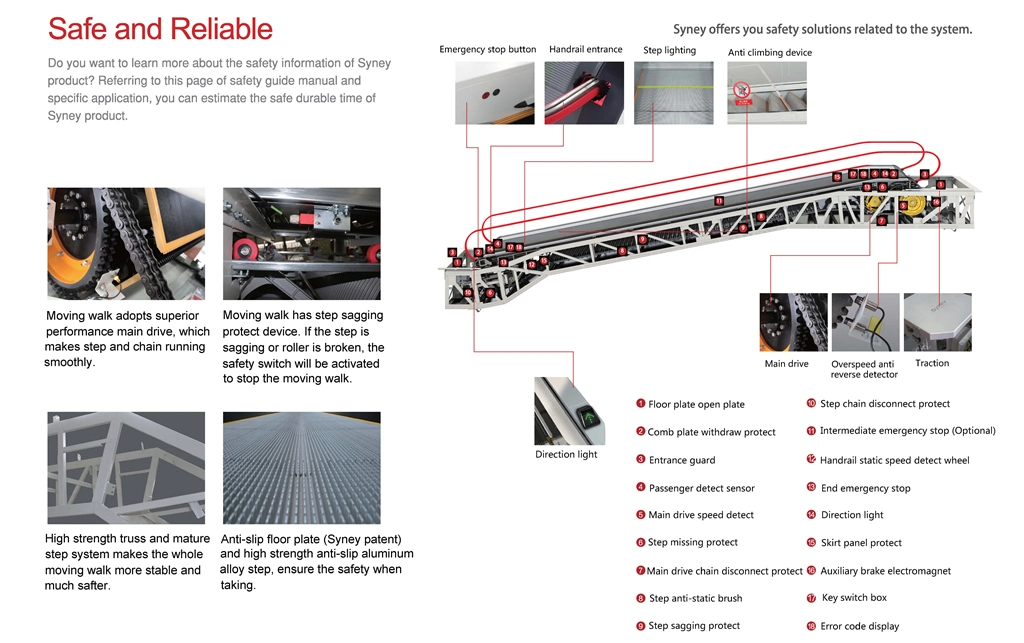

Safety measures

Functions

| Standard safety functions | |||||

| 1 | Emergency Stop Button | Yes | 19 | Machine Room Protect Board | Yes |

| 2 | Handrail Entry Contact | Yes | 20 | Step Light | Yes |

| 3 | Broken Step Chain Protection | Yes | 21 | Skirt Panel Contact | Yes |

| 4 | Comb Plate Contact | Yes | 22 | Step Yellow Safety Line | Yes |

| 5 | Inspection Socket | Yes | 23 | Alarm Bell When Start | Yes |

| 6 | Phase Failure and Phase Stagger Protection | Yes | 24 | Floor Plate Open Device | Yes |

| 7 | Step Sag Contact | Yes | 25 | Alarm Signs | Yes |

| 8 | Stop Button | Yes | 26 | Main Driving Chain Broken Protect Device | Yes |

| 9 | Main Power Switch | Yes | 27 | Overspeed Lowspeed Protection | Yes |

| 10 | Circuit Grounding Device | Yes | 28 | Step Static-free Device | Yes |

| 11 | Non-operational Reversal Safety Device | Yes | 29 | Handrail Belt Speed Detect Protection | Yes |

| 12 | Overload Protect | Yes | 30 | Floor Plate Open Detect Device | Yes |

| 13 | Portable Lamp and Socket | Yes | 31 | Step Missing Detect Protection | Yes |

| 14 | Handrail Belt Antistatic Device | Yes | 32 | Working Brake Open Detect Device | Yes |

| 15 | Traction Flywheel Cover Open Detect Switch | Yes | 33 | Skirt Panel Anti Clamp Device | Yes |

| 16 | Maintenance Power Supply Socket | Yes | 34 | Working Brake | Yes |

| 17 | Step Anti Bounce Device | Yes | 35 | Auto Lubricating Device | Yes |

| 18 | Safety Signs | Yes | |||

| Optional functions | |||||

| 1 | Blocking device | ○ | 8 | Handrail lightening | ○ |

| 2 | Anti-climb device | ○ | 9 | Direction indicator | ○ |

| 3 | Anti-climb device is Not preset. | Yes/No | 10 | Oil-water separator | ○ |

| 4 | Vertical protect board | ○ | 11 | Liquid level switch | ○ |

| 5 | Handrail disconnect protect device | ○ | 12 | Heating device | ○ |

| 6 | Brake shoe wearing detection | ○ | 13 | Cladding | ○ |

| 7 | Auxiliary brake | ○ | |||

Production and shipping

From the raw material getting into factory to finished products getting out to customers, Syney has a strict operation system to control each steps.No rejected raw material will be accpeted! When raw material comes to factory, QC department will check all the materials, once any fault items found, it will be returned to suppliers at once. Only qualified material will get into raw material warehouse.Production managementEvery week, production department will make the production plan and update the schedule of online products. There is daigital board in each workshop showing the production plan everyday. In this way, from workers to managers all clearly know which project is online now.Every moring, managers will guide the workers to run for 15 minutes first to refresh. Then check the machines status before operation and check again after one day job. PackingAll parts are packed in solid plywood boxes, which can stand long time sea shipping and fumigation free. For some important parts like control cabinet, door operator and motor, parts will be covered by a strong film first, with desiccant, before put into boxes.Quality control1) All raw materials will be checked before get into warehouse. And bulk electronic product do sampling inspection. All parts must have qualified certificate from suppliers. QC1 is responsible for this.2) During production stage, QC2 will check commissioning for each elevator, escalator and moving walks.3) After elevator and escalator finished, QC3 will test the match of elevator motor and control cabinet, and the running condition of escalator and moving walks.4) After packed, QC4 will check package condition for each parts, and takes photo for further reference.5) When delivery, QC5 will check if all parts packed in container to avoid any missing, and takes photo for further reference.

Production and assembling

Packing and shipping

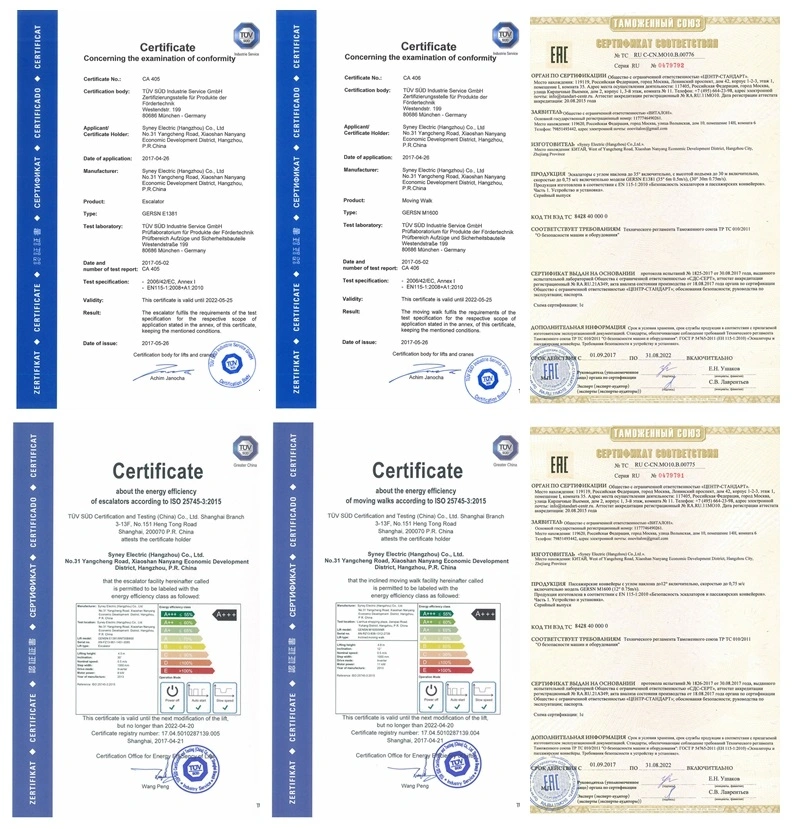

Certificates

CE Certificate of escalator and moving walk/ passenger conveyorCE Certificate of energy-efficiency of lifts: A+++EAC Certificate of escalator and moving walk/ passenger conveyor

Company Profile

SYNEY ELEVATOR is the leading elevator & escalator manufacturer in China. Our main products include passenger elevator, freight elevator, goods lift, panoramic elevator, observation lift, hospital bed elevator, villa home lift, escalator, waving escalator and moving walk.etc. Depending on advanced technologies, modern equipments, standardized management, and perfect marketing customer service network, the business of Syney Elevator has been improving steadily, not only covers the whole country, but also has been sold to Russia, Middle East, Southeast Asia, Korea and America, etc, becoming one of elevator enterprises with the highest potential. The enterprise has two manufacturing factories. The registered capital is USD 35 million, covering nearly 99000 square meters, with over 80 engineering technicians and nearly 30 senior managers.

Projects

Prev: Stainless Steel Shaftless Screw Conveyor

Next: Screw Rice Belt Conveyor Shaftless Screw Conveyor Tubular Screw Conveyor

Our Contact

Send now